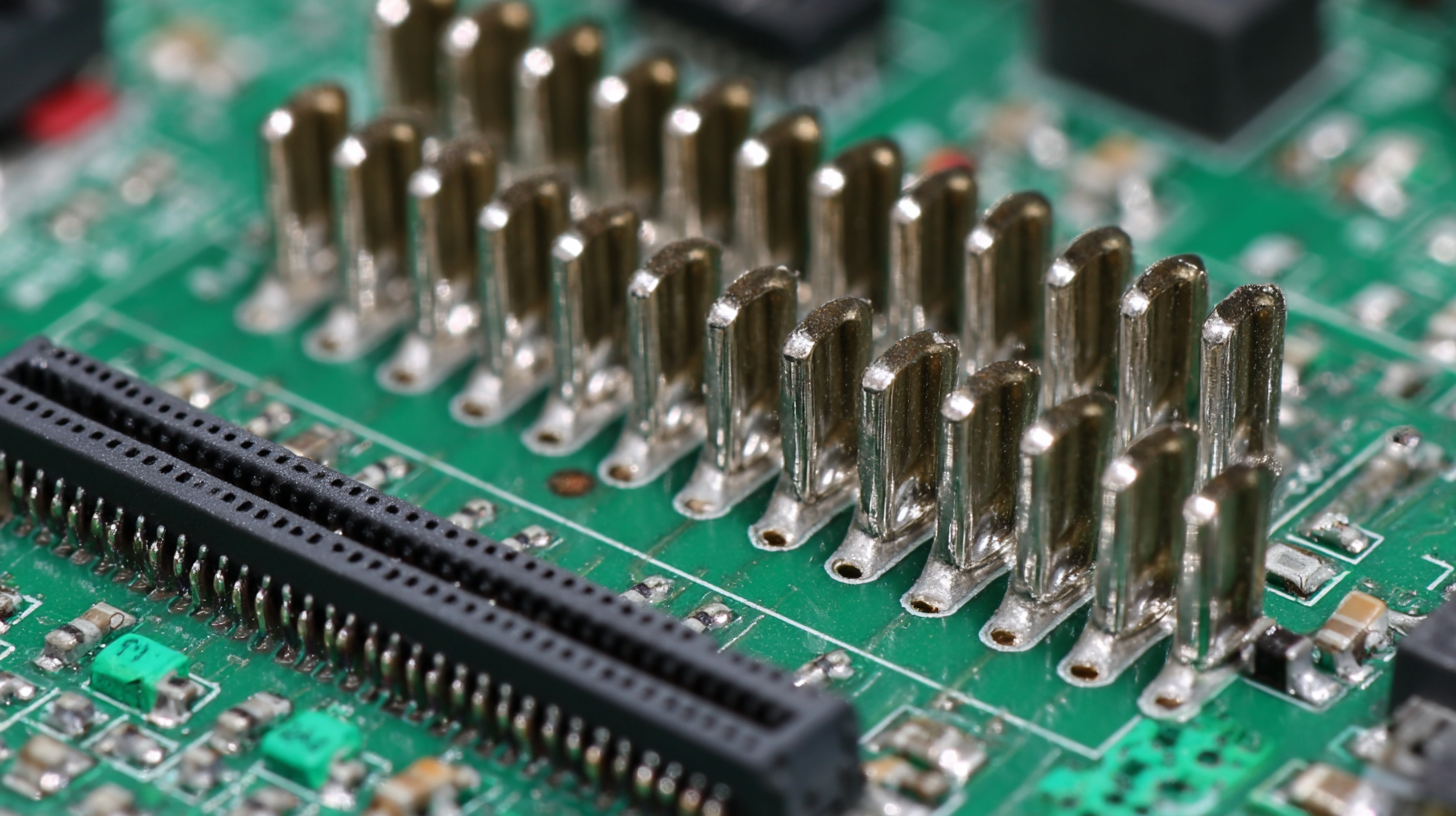

The 2mm Pin Header Socket has emerged as an essential component in modern electronics, offering unparalleled versatility and efficiency across a wide range of applications. According to a recent report by MarketsandMarkets, the global connector market is projected to reach $62.2 billion by 2025, driven by the increasing demand for compact and reliable connections in consumer electronics, automotive, and industrial sectors.

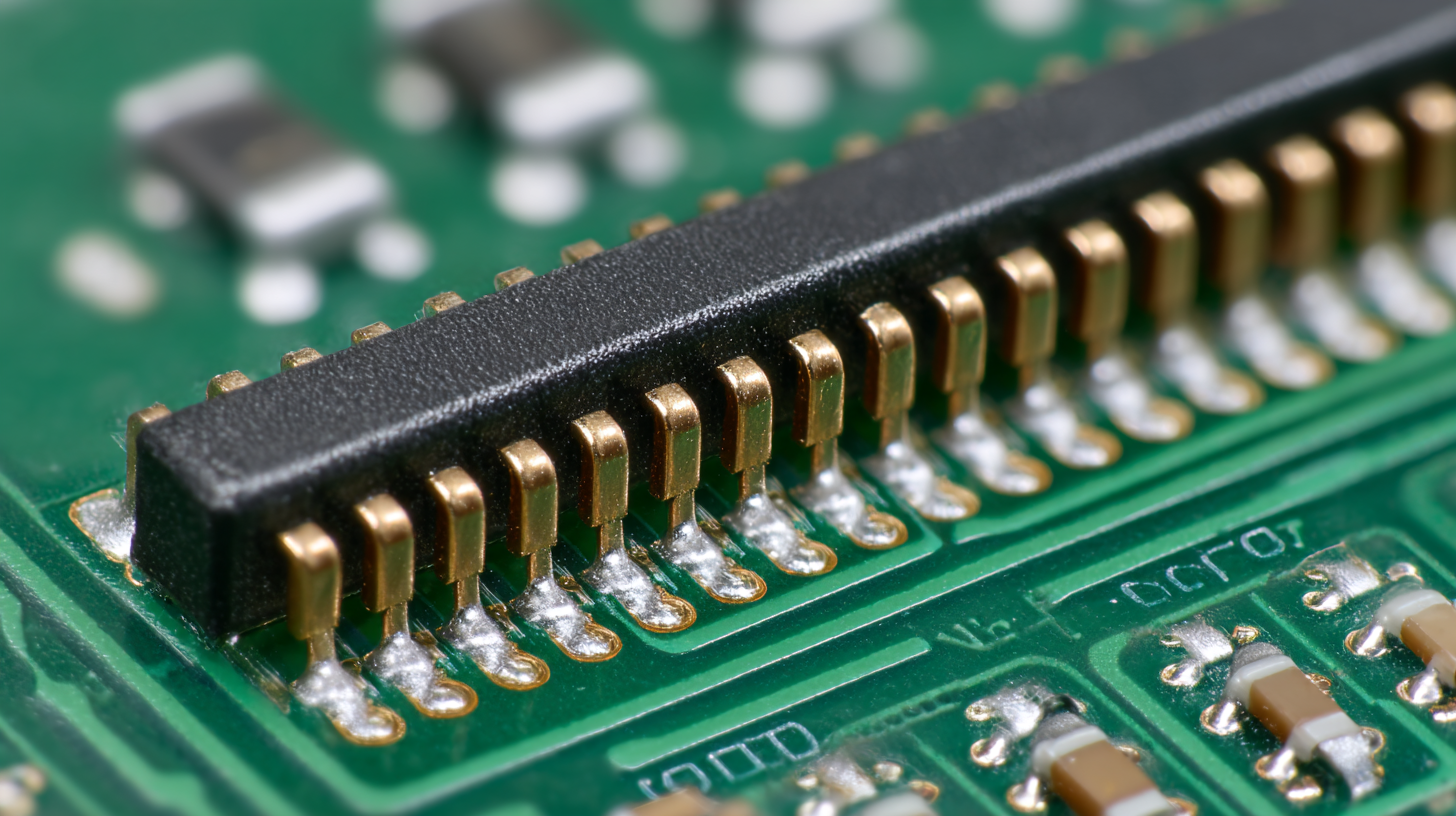

The 2mm Pin Header Socket, with its compact size and compatibility with various PCB layouts, allows for efficient data transfer and power connections, making it ideal for applications in IoT devices and automation. Furthermore, its ability to support high-density configurations while ensuring reliable performance under rigorous conditions underscores its importance in adhering to industry standards.

As we delve deeper into the numerous advantages and applications of the 2mm Pin Header Socket, we will explore how this surprisingly simple component is pivotal to the advancement of modern electronic designs.

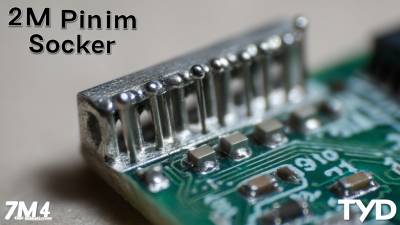

When embarking on a project that requires the use of 2mm pin header sockets, it's crucial to identify the right component to ensure optimal performance and compatibility. Start by assessing the specifications of your PCB (Printed Circuit Board) and the components you plan to connect. Pay special attention to the number of pins needed, as 2mm pin header sockets come in various configurations—from single rows to multi-row arrangements. Understanding your space constraints and any potential alignment issues will help narrow down your options.

Additionally, consider the technical aspects such as the current and voltage ratings of the socket. Different applications may require sockets that can handle specific electrical loads or environmental conditions. Materials and plating types can also affect the durability and conductivity of the connections. By evaluating these factors, you can confidently select a 2mm pin header socket that aligns with your project's requirements, ensuring reliable connectivity and performance in your electronic design.

| Parameter | Description | Application | Material | Current Rating | Operating Temperature |

|---|---|---|---|---|---|

| Pin Size | 2mm pin headers | General electronic connections | Phosphor Bronze | 1A per pin | -40°C to 105°C |

| Pitch | 2mm pitch | Compact PCB designs | FR-4 with gold plating | 0.5A per pin | -40°C to 85°C |

| Mounting Type | Through Hole and Surface Mount | Variety of circuit boards | Nylon housing | 2A per pin | 0°C to 80°C |

| Contact Finish | Gold or Tin | Connector longevity and reliability | Gold over Nickel | 1.5A per pin | -55°C to 125°C |

When it comes to creating reliable connections in modern electronics, mastering the art of soldering 2mm pin header sockets is essential. These connectors are versatile components often used in various applications, from connecting sensors to microcontrollers. A well-soldered connection ensures excellent electrical performance, reducing the risk of signal loss and increasing the lifespan of the component.

**Tip 1:** Before starting the soldering process, ensure that both the pin header socket and the PCB are clean. Use isopropyl alcohol on a lint-free cloth to remove any oxidation or debris, promoting a stronger bond and preventing potential connectivity issues.

The technique of soldering these sockets involves careful attention to the heat applied and the duration of exposure. It’s crucial to allow the solder to flow smoothly, creating a solid joint without overheating the components.

**Tip 2:** Use a soldering iron with a fine tip for precision. Maintain a steady hand to avoid slippage, and always let the solder cool naturally before moving the assembly to ensure that the connection forms properly and securely.

This chart illustrates the importance rating of various factors associated with the use of 2mm pin header sockets in modern electronics, highlighting their reliability, ease of soldering, cost effectiveness, versatility, and availability.

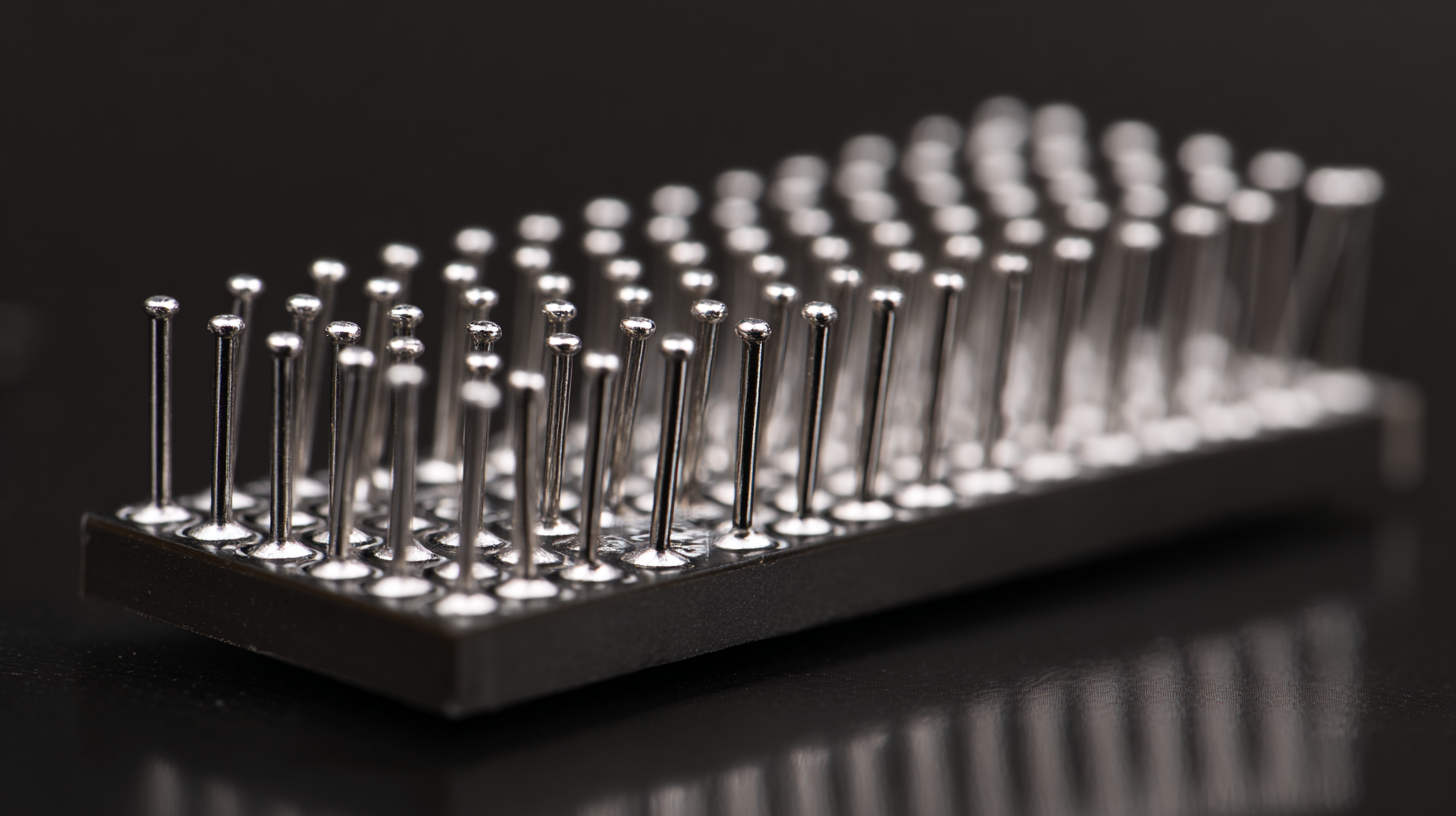

When integrating 2mm pin header sockets into custom PCB designs, understanding their layout and placement is essential for optimal functionality. The first step is to assess the connection requirements of your project; these sockets are versatile and can accommodate various components. Proper planning of the connection points on the PCB, including spacing and orientation, is crucial. Utilize a software tool for designing the PCB to visualize the placement of the pin headers and how they will interface with other components.

Additionally, ensuring proper soldering techniques is vital for incorporating 2mm pin header sockets effectively. The pins should align perfectly with the pads on the PCB to guarantee a solid electrical connection. Pay attention to the thermal properties during the soldering process to avoid damage to the socket or surrounding components. By keeping these elements in mind, designers can seamlessly integrate 2mm pin header sockets into their PCB layouts, enhancing the overall reliability and versatility of modern electronic applications.

Troubleshooting common issues with 2mm pin header sockets is essential for ensuring reliable connections in modern electronics. One of the most frequent problems is poor contact, which can lead to intermittent connections. According to a report by ANSI/IPC-A-610, approximately 30% of electronic assembly defects are attributed to faulty connections. To mitigate this, users should regularly check for dirt or oxidation on the pins, as contaminants can significantly impair conductivity. Utilizing cleaning solutions designed for electronic components can help maintain optimal performance.

Troubleshooting common issues with 2mm pin header sockets is essential for ensuring reliable connections in modern electronics. One of the most frequent problems is poor contact, which can lead to intermittent connections. According to a report by ANSI/IPC-A-610, approximately 30% of electronic assembly defects are attributed to faulty connections. To mitigate this, users should regularly check for dirt or oxidation on the pins, as contaminants can significantly impair conductivity. Utilizing cleaning solutions designed for electronic components can help maintain optimal performance.

Another common issue is the physical mismatch between headers and sockets, which can arise from manufacturing tolerances. A study conducted by the Consumer Technology Association indicated that improper alignment is responsible for around 20% of connection failures in electronic circuits. To address this, it's crucial to ensure that pin headers are compatible with the corresponding sockets, and to inspect for any signs of bending or damage to the pins prior to connections. Regular maintenance and inspection can prevent many issues, allowing for a smoother operation of devices relying on 2mm pin header sockets.

Maximizing the performance and lifespan of 2mm pin header sockets requires careful attention to several key factors. First and foremost, selecting high-quality materials is essential. Look for sockets made from durable plastics and robust metal contacts that can withstand frequent plugging and unplugging. Additionally, ensure that the contact resistance is minimized, as this can lead to better conductivity and reduced heat generation, which is crucial for long-term reliability.

Proper installation techniques also play a critical role in enhancing performance. It is important to align the pin headers correctly and avoid excessive force during insertion. Utilizing appropriate soldering methods can prevent cold joints, which may lead to intermittent connectivity issues. Furthermore, maintaining a clean working environment helps to avoid contamination and oxidation, which can compromise the performance of the sockets over time. Regular inspections and preventive maintenance can identify wear and potential failures early, ensuring that the pin header sockets operate at their best throughout their lifespan.