In the rapidly evolving landscape of industrial technology, the demand for reliable and efficient connectivity solutions has never been more critical. As we approach 2025, the relevance of Industrial Connectors continues to rise, driven by advancements in automation, IoT, and smart manufacturing. Renowned expert in the field, Dr. Emily Carter, emphasizes, “The right Industrial Connector can make or break the efficiency of an entire system. Choosing wisely is paramount for future-proofing industrial operations."

This article delves into the top Industrial Connectors anticipated to dominate the market in 2025. We will explore key features that set these connectors apart, ensuring they meet the rigorous demands of modern industrial applications. Furthermore, the buyer’s guide section aims to equip decision-makers with the necessary insights to select the most suitable Industrial Connectors for their specific needs, addressing factors such as durability, compatibility, and cost-effectiveness.

As the industry gears up for more interconnected systems, understanding the nuances of Industrial Connectors will be essential for engineers and procurement teams alike. Join us as we unfold the pivotal characteristics and critical considerations that will shape the future of connectivity in industrial settings.

The industrial connectors market is experiencing substantial growth, anticipated to reach USD 12 billion by 2025, propelled by increasing automation across various industries. The dominant trend is the integration of smart technologies into connectors, enhancing communication and reducing downtime for machinery. Such advancements are crucial, as reported by industry analysts, highlighting that 60% of industrial downtime can be attributed to poor connectivity issues. Therefore, it is essential for buyers to focus on connectors that support high data speeds and robust environmental protection.

When considering the purchase of industrial connectors, it is critical to evaluate several key features. First, the connector's compatibility with existing systems should not be overlooked, ensuring seamless integration. Additionally, factors like IP ratings, operating temperature ranges, and mechanical durability are vital in assessing reliability in demanding environments. With over 40% of industries expected to implement automation solutions by 2025, the demand for versatile connectors that can withstand harsh conditions will only increase.

**Tip**: Prioritize connectors that offer modular designs. They provide flexibility for future upgrades and are often easier to install and maintain, ultimately reducing operational costs. Understanding the specific requirements of your operational environment, including voltage levels and frequency, can lead to more informed purchasing decisions, ensuring longevity and optimal performance.

The industrial connectors market is poised for significant growth, driven by the increasing demand for automation and improved connectivity in various sectors. As industries continue to embrace digital transformation, the need for reliable and efficient connectors that can withstand harsh environments is paramount. Projections indicate a robust growth rate over the next few years as companies invest in modernizing their infrastructure, thereby enhancing productivity and operational efficiency.

Several key players are emerging in the industrial connectors sphere, focusing on innovation and technological advancements to capture market share. These manufacturers are concentrating on developing connectors that offer enhanced features such as higher durability, resistance to extreme conditions, and ease of installation. Additionally, the rising trend of Industry 4.0 is influencing the design and functionality of connectors, pushing for solutions that can integrate seamlessly with IoT devices. As sustainability becomes a focal point, the adoption of eco-friendly materials and practices is also gaining traction among leading manufacturers.

When selecting industrial connectors, durability and performance metrics are paramount for ensuring reliability in challenging environments. According to a report by MarketsandMarkets, the global industrial connectors market is projected to reach $9.5 billion by 2025, driven largely by the growing demand for robust, high-performance connectors in sectors such as manufacturing, transportation, and energy. Industrial connectors must withstand extreme conditions, including temperature fluctuations, humidity, and physical stress. A connector's ingress protection (IP) rating, which measures its resistance to dust and moisture, is often considered a critical factor. Ratings such as IP67 or IP68 indicate that the connectors can function effectively in harsh environments, making them suitable for outdoor and factory settings.

In addition to durability, the performance metrics of industrial connectors have a significant impact on their effectiveness. Parameters like electrical conductivity, thermal performance, and mechanical resistance are essential for ensuring that connectors meet the stringent demands of modern applications. Research indicates that connectors with lower contact resistance can enhance overall system efficiency, significantly reducing energy losses in power applications. Furthermore, features such as quick-lock mechanisms and high mating cycles further enhance user experience and long-term reliability. With these features in mind, buyers can make informed decisions, prioritizing connectors that guarantee both durability and performance tailored to their specific industrial needs.

Industrial connectors are crucial components in various manufacturing and automation processes, facilitating reliable electrical and data connections. Understanding the pros and cons of different connector designs is essential for selecting the right type for specific applications. A recent market research report indicates that the global industrial connector market is projected to reach approximately $4.2 billion by 2025, driven by the increasing demand for robust interconnect solutions in sectors such as transportation, oil and gas, and robotics.

There are several popular types of industrial connectors, each with unique advantages and disadvantages. For instance, circular connectors are known for their versatility and strong mechanical coupling, making them suitable for dynamic applications. However, their bulkiness can be a downside in tighter spaces. In contrast, rectangular connectors are more compact and offer high-density options, yet they may not provide the same level of environmental protection as their cylindrical counterparts.

Additionally, modular connectors are growing in popularity due to their customizable configurations, which allow for easy adaptation to various applications, though they may require more intricate assembly processes.

Choosing the right industrial connector also involves evaluating environmental factors such as moisture, dust exposure, and temperature extremes. Connectors with higher IP ratings provide better protection against these elements, ensuring longevity and reliability.

According to forecasts, connectors with enhanced sealing properties are expected to gain significant traction, catering to industries where durability is paramount. As the demand for efficient and high-performance electronic connections continues to evolve, understanding the distinct characteristics of each connector type becomes increasingly vital for manufacturers and engineers alike.

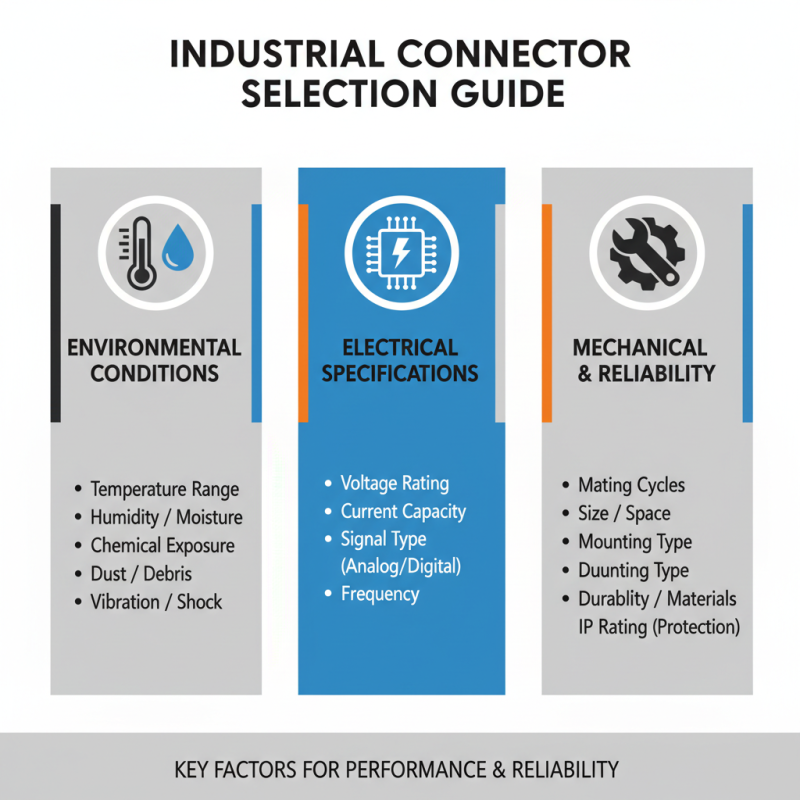

When selecting the right industrial connector for specific applications, it is essential to consider several key factors that will significantly impact performance and reliability. Firstly, assessing the environmental conditions where the connector will operate is crucial. Factors such as temperature, humidity, and exposure to chemicals should guide your choice, as connectors come in various designs tailored for different environments. Additionally, understanding the electrical specifications, including voltage ratings and current carrying capacities, will ensure that the connector is suitable for the intended use, preventing potential failures and safety hazards.

Another critical aspect to consider is the connector's mechanical characteristics, such as locking mechanisms and mating cycles. A robust connector should provide secure connections that can withstand vibrations and shocks, which are common in industrial settings. Furthermore, ease of installation and maintenance should not be overlooked; connectors that offer straightforward assembly and disassembly can save time and reduce labor costs. Lastly, compatibility with existing systems cannot be understated, as selecting a connector that integrates seamlessly with other components will enhance operational efficiency. By carefully evaluating these factors, you can make an informed decision that supports the demands of your specific application.