In today's industrial automation landscape, selecting the right PLC connector is crucial for ensuring seamless communication, reliability, and efficiency in operations. According to a recent report by MarketsandMarkets, the global industrial automation market is expected to reach $295 billion by 2026, driven by increasing adoption of advanced technologies and the need for enhanced productivity. PLC connectors play a pivotal role in this ecosystem, enabling the connection of various components within automation systems. As industries increasingly rely on automation solutions, understanding the specific requirements for PLC connectors—such as durability, compatibility, and ease of installation—becomes imperative. This article will guide you through the key considerations when choosing PLC connectors that align with your industrial automation needs, ultimately enhancing system performance and reducing downtime.

Programmable Logic Controllers (PLCs) are central to modern industrial automation, requiring reliable connections for optimal performance. Understanding the basics of PLC connectors is essential for selecting the right type for specific applications. These connectors serve as the backbone for communication between the PLC and various field devices, such as sensors, actuators, and other machinery, ensuring seamless data transfer and control.

Programmable Logic Controllers (PLCs) are central to modern industrial automation, requiring reliable connections for optimal performance. Understanding the basics of PLC connectors is essential for selecting the right type for specific applications. These connectors serve as the backbone for communication between the PLC and various field devices, such as sensors, actuators, and other machinery, ensuring seamless data transfer and control.

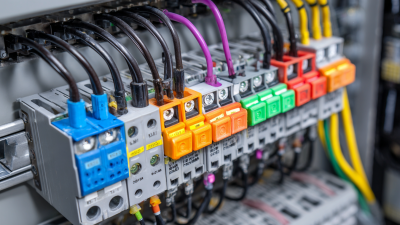

When choosing PLC connectors, it is critical to consider factors like the application's environmental conditions, connector types (e.g., terminal block, DIN rail, or rugged connectors), and the number of connections required. Different connectors offer varying levels of durability, waterproofing, and resistance to vibrations and electrical interference. Additionally, matching the connector's specifications with the PLC's input/output requirements guarantees that data is transmitted efficiently, minimizing downtime and enhancing overall system reliability. By understanding these fundamental aspects, industrial professionals can effectively navigate their options and select connectors that best meet their automation needs.

When selecting the right PLC connector for your industrial automation needs, it's crucial to first identify your specific automation requirements. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $295 billion by 2025, reflecting the increasing demand for streamlined operations and enhanced efficiency. This surge emphasizes the necessity for reliable and efficient PLC connectors that can withstand harsh industrial environments while ensuring optimal connectivity.

Different applications will have varying demands on connector types based on factors such as data transmission speed, environmental conditions, and space constraints. For instance, connectors designed for high-speed data transfer are essential in applications involving real-time monitoring and control, where delays can result in operational inefficiencies.

Additionally, connectors rated for extreme temperatures and resistance to moisture, dust, and chemicals are vital for industries such as pharmaceuticals and food processing, where safety and compliance standards are stringent.

Utilizing industry standards, such as those set by the IEC (International Electrotechnical Commission), can further help in selecting the right connector that aligns with your specific automation needs.

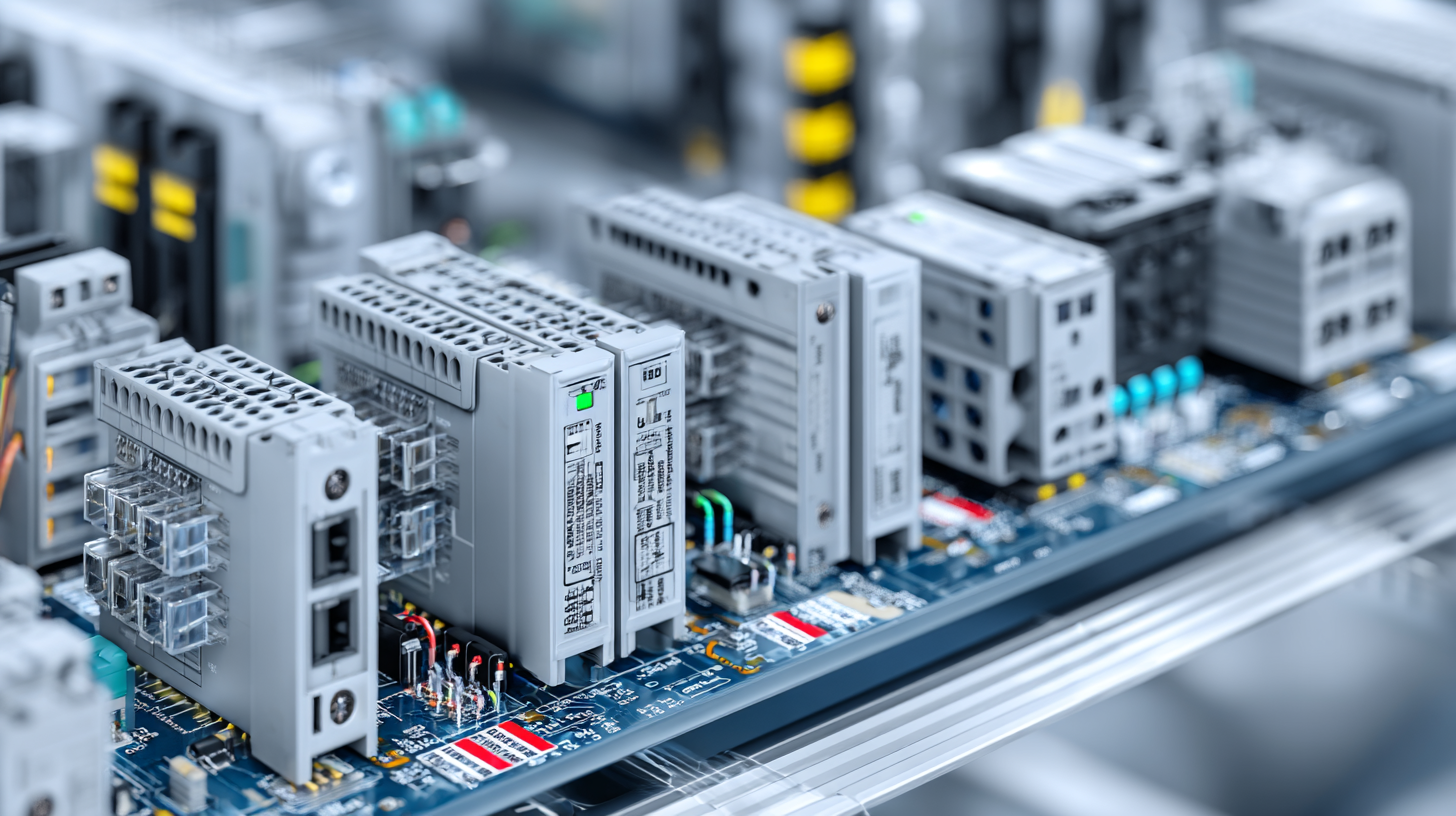

When selecting the right PLC connector for industrial automation needs, there are several key features to consider that can significantly impact system performance and reliability. Firstly, connector compatibility is vital; ensure that the connectors are designed to work seamlessly with the specific PLC and its associated modules. For instance, modular systems like the SINAMICS S210 servo drive need connectors that can handle high dynamic applications efficiently, addressing power requirements from 50 W to 7 kW.

Another critical factor is environmental resilience. Connectors should be rated for the specific conditions of the operating environment, such as temperature variations, humidity, and potential exposure to chemicals. In harsh industrial settings, connectors that meet IP ratings for dust and water ingress will help maintain the integrity of the connections and reduce downtime.

Tips: When choosing PLC connectors, consider those with easy-to-use locking mechanisms to ensure secure and quick connections, especially in fast-paced environments. Additionally, always refer to updated technical specifications and industry reports to remain informed about the latest connector innovations and standards, which can enhance the efficiency of your automation systems.

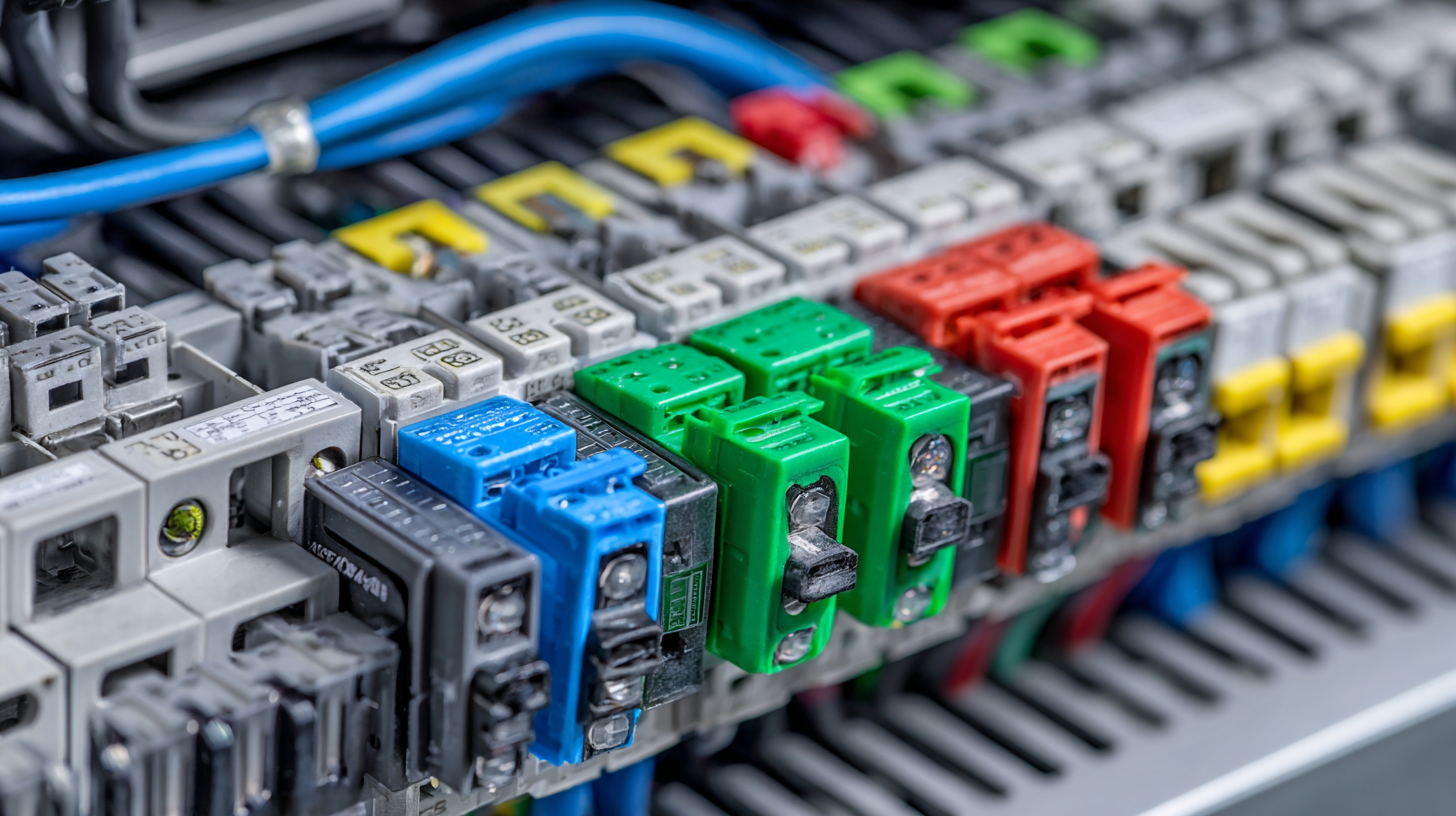

When selecting the right PLC connector for your industrial automation needs, it's essential to understand the different types available in the market. PLC connectors come in various configurations, including screw terminal, spring clamp, and push-in types, each catering to specific installation requirements and operational environments.

Screw terminal connectors, for instance, are favored for their reliability and strong mechanical connection, making them ideal for applications that require a robust setup in harsh conditions.

On the other hand, spring clamp connectors offer quick and easy wiring, which can significantly reduce installation time, especially in projects where efficiency is crucial.

Push-in connectors, known for their user-friendly design, allow for tool-less connections, making them perfect for environments where frequent changes or maintenance are necessary.

By comparing these connector types, industrial automation professionals can make informed decisions tailored to their specific applications, ensuring optimal performance and reliability in their PLC systems.

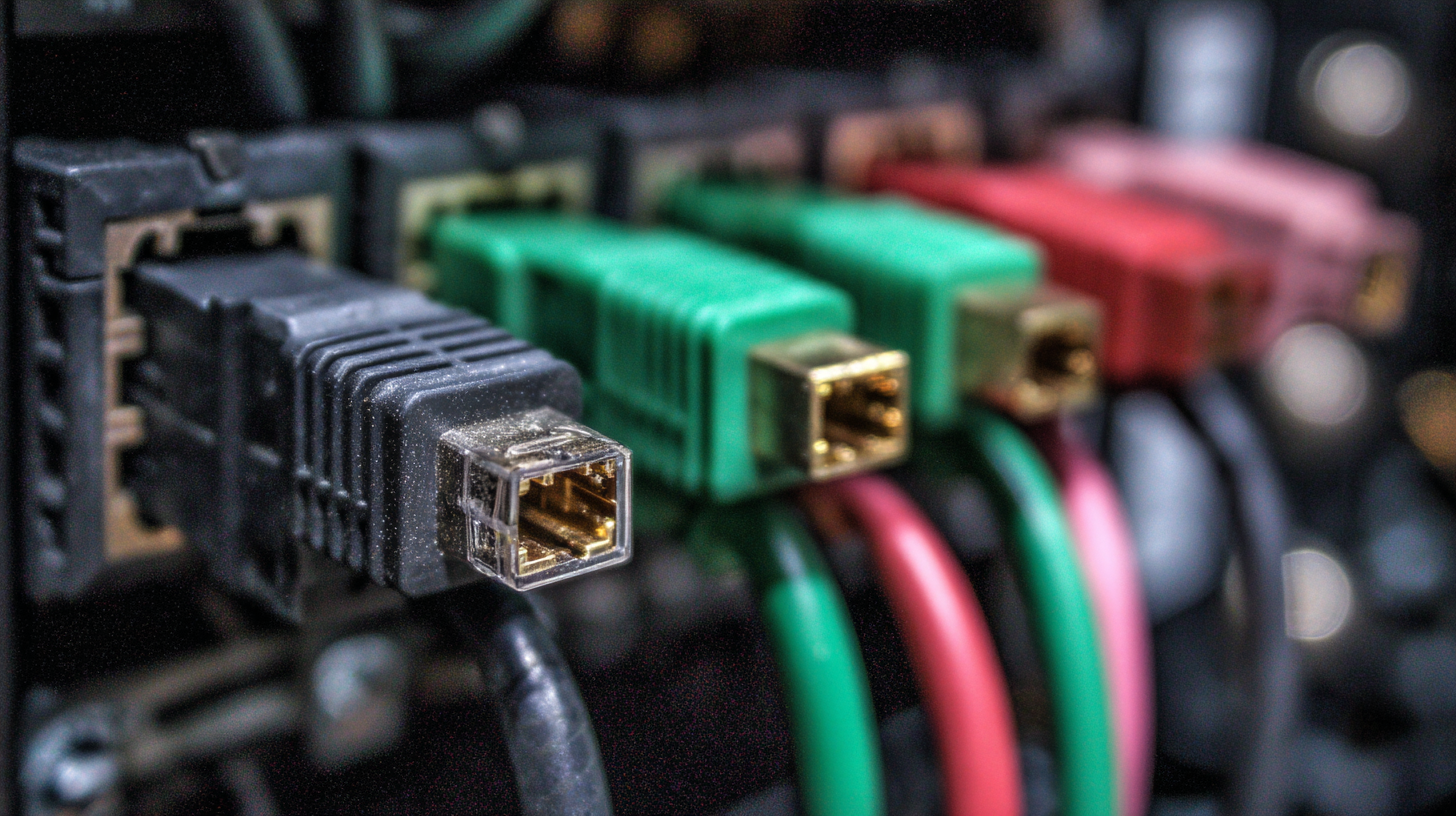

When selecting the right PLC connector for your industrial automation needs, ensuring compatibility and reliability is paramount. According to a report by MarketsandMarkets, the global industrial automation market is expected to reach $295.2 billion by 2025, underscoring the growing demand for effective and durable connectivity solutions. This increase highlights the necessity of choosing PLC connectors that not only fit the equipment but also withstand the harsh conditions often presented in industrial environments.

One of the key considerations when selecting a PLC connector is to verify the specifications against your specific application requirements. It’s vital to check for factors such as temperature range, operating voltage, and environmental resistance, as connectors must function optimally to support uninterrupted operations. For instance, connectors rated for IP67 or higher provide additional protection against dust and water ingress, which is crucial in manufacturing setups where such elements are prevalent. Moreover, ensuring the connectors meet industry standards, such as IEC 60947, can significantly enhance reliability and compatibility, thereby reducing long-term maintenance costs and downtimes.

| Connector Type | Pin Count | Voltage Rating (V) | Current Rating (A) | Material | Temperature Rating (°C) | IP Rating |

|---|---|---|---|---|---|---|

| M12 Connector | 4, 5, 8 | 250 | 4, 8, 12 | Plastic/Metal | -40 to +85 | IP67 |

| D-Sub Connector | 9, 15, 25 | 30 | 1.5 | Metal | -55 to +125 | IP40 |

| RJ45 Connector | 8 | 50 | 1.5 | Plastic | -20 to +70 | IP20 |

| Terminal Block Connector | 2-12 | 600 | 30 | Plastic/Metal | -40 to +105 | IP00 |