In the rapidly evolving electronics industry, finding reliable suppliers for critical components like pin headers is essential for maintaining product quality and performance.

Pin headers, often used in various applications ranging from simple connectors to complex circuit boards, play a pivotal role in ensuring seamless electronic connectivity.

As manufacturers strive to enhance their offerings, understanding the advantages of after-sales service and managing repair costs becomes imperative.

Reliable suppliers not only provide high-quality pin headers but also support their clients with efficient after-sales assistance, which can significantly reduce long-term operational costs.

This blog aims to explore the importance of selecting dependable suppliers for pin headers, examining how their after-sales services can positively impact repair expenses and foster enduring partnerships in the electronics sector.

Pin headers, often used in various applications ranging from simple connectors to complex circuit boards, play a pivotal role in ensuring seamless electronic connectivity.

As manufacturers strive to enhance their offerings, understanding the advantages of after-sales service and managing repair costs becomes imperative.

Reliable suppliers not only provide high-quality pin headers but also support their clients with efficient after-sales assistance, which can significantly reduce long-term operational costs.

This blog aims to explore the importance of selecting dependable suppliers for pin headers, examining how their after-sales services can positively impact repair expenses and foster enduring partnerships in the electronics sector.

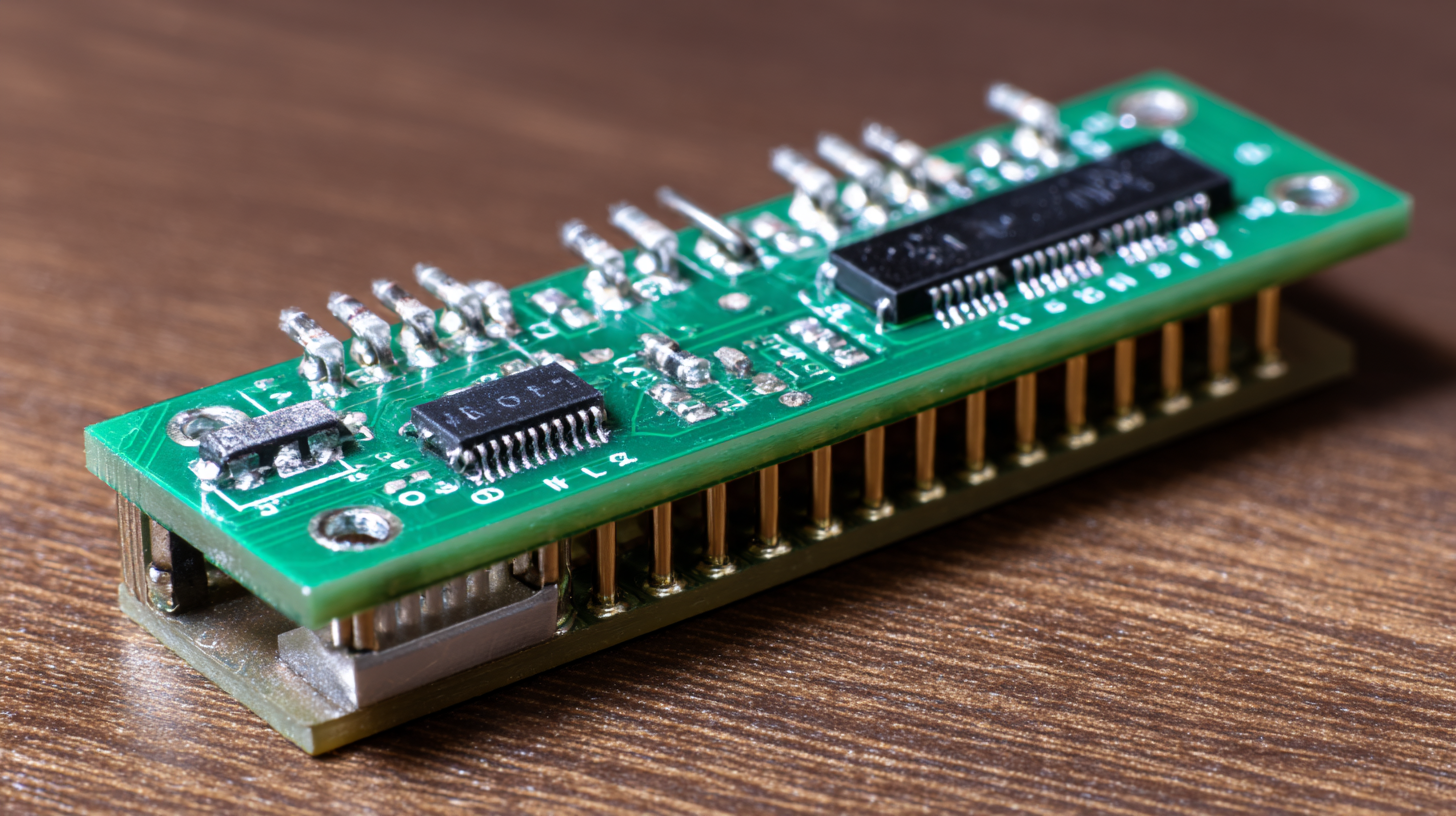

When it comes to sourcing pin headers in the electronics industry, understanding the quality standards is crucial for ensuring reliability and longevity. Global markets present a diverse range of products; hence, familiarizing oneself with international standards such as IPC and ISO can provide a strong foundation for making informed purchasing decisions. These standards not only cover physical dimensions but also material purity, environmental compliance, and performance specifications.

**Tip 1:** Always request test reports and certifications from suppliers to verify that their products meet the required standards. This due diligence can save you from potential supply chain issues and ensure that you receive components that perform as expected in your applications.

In addition to knowing the standards, it's vital to assess the supplier's track record in quality control. Understanding their manufacturing processes will give you insight into their reliability and dependability as a partner. Look for suppliers who implement strict quality assurance protocols and have experience in the specific types of pin headers you need.

**Tip 2:** Engage with suppliers through audits or factory visits if possible. This step not only helps verify their adherence to quality standards but also builds a stronger relationship, fostering better communication and trust in the long run.

When sourcing pin headers in the electronics industry, evaluating potential suppliers for

consistency and reliability is paramount.

According to a recent report from Research and Markets, the global pin header market is anticipated to grow substantially,

projected to reach $1.5 billion by 2025. With this growth comes a plethora of suppliers, making it essential for

manufacturers to sift through options and identify those that can deliver consistent quality over time.

A key component in this evaluation process is the assessment of suppliers' operational performances, which often involves metrics

such as on-time delivery rates and defect rates. A study by Gartner illustrates that companies

prioritizing reliability in their supply chain partners see a reduction of up to 30% in production delays. Engaging with

suppliers that have demonstrated robust quality control processes, such as ISO certifications,

can significantly enhance the likelihood of consistent product supply, ensuring that pin headers meet both engineering specifications

and customer expectations. Emphasizing these foundational criteria will not only streamline the production process but also foster long-term

partnerships critical for sustained growth in the competitive electronics market.

In the electronics sector, ensuring product quality and compliance with industry standards is paramount. Certifications serve as a crucial indicator of a supplier’s reliability. They demonstrate that a company adheres to specific manufacturing practices, safety regulations, and quality control measures. For instance, certifications like ISO 9001 or IPC standards not only highlight a supplier's commitment to quality management but also provide the necessary assurance that their pin headers meet rigorous performance requirements. This is especially vital in an industry where component failure can lead to significant operational disruptions.

Furthermore, understanding the importance of certifications helps in establishing trust between manufacturers and suppliers. Companies that prioritize working with certified suppliers often experience fewer risks related to faulty components, which can result in costly recalls or damages. In addition, certifications can streamline the procurement process, as they provide a benchmark for evaluating potential suppliers. By focusing on certified providers in the search for the best pin headers, businesses can enhance their overall product reliability and maintain their competitive edge in the electronics market.

| Supplier Location | Product Quality Certification | Customer Ratings | Delivery Time (days) | Price Range ($) |

|---|---|---|---|---|

| USA | ISO 9001 | 4.8/5 | 7 | 50 - 100 |

| Germany | DIN EN 9100 | 4.6/5 | 10 | 60 - 120 |

| Japan | JIS Q 9001 | 4.9/5 | 5 | 70 - 150 |

| China | ISO 14001 | 4.5/5 | 14 | 30 - 80 |

| South Korea | ISO 45001 | 4.7/5 | 8 | 40 - 90 |

In today's fast-paced electronics industry, finding reliable suppliers for critical components like pin headers is essential for maintaining product quality and operational efficiency. To streamline this process, businesses are increasingly leveraging technology for supplier verification and quality control. Advanced digital tools allow companies to assess potential suppliers by examining their production capabilities, certifications, and compliance records. This initial vetting process helps narrow down options to those that are most reliable, ultimately saving time and resources.

Once a shortlist of potential suppliers is established, technology continues to play a crucial role in ensuring ongoing quality control. Utilizing automated systems for inspections and real-time monitoring of production processes allows companies to maintain high standards without sacrificing efficiency. Additionally, data analytics can provide insights into supplier performance, helping businesses identify and address any emerging issues before they impact production. By integrating these technological solutions into the supplier management process, companies not only enhance their overall operational reliability but also foster fruitful long-term partnerships with their suppliers.

Building long-lasting relationships with trusted suppliers in China is essential for ensuring reliability in sourcing the best pin headers for the electronics industry. Establishing these relationships requires a commitment to endurance and a shared vision of improving business operations over time. As highlighted by industry leaders, navigating the complexities of doing business in China means being flexible and open to adapting strategies based on evolving market conditions.

Tip: Focus on cultivating a relationship that values transparency. Regular communication with suppliers can facilitate a better understanding of each other's capabilities and expectations, leading to smoother transactions and collaboration.

Another important aspect is aligning your values with those of your suppliers. This alignment not only strengthens partnerships but also ensures that both parties are committed to enhancing working conditions and fostering sustainable practices. By prioritizing these shared goals, businesses can work together to innovate effectively and respond to the rapid changes in the global supply chain landscape.

Tip: Consider conducting regular assessments of your suppliers’ operations to ensure they meet both your quality standards and ethical expectations. This proactive approach can help maintain the integrity of your supply chain and reinforce trust between partners.

This bar chart illustrates the reliability ratings of various suppliers in the electronics industry, focusing specifically on pin header manufacturers. The ratings are based on factors such as product quality, delivery time, and customer service.