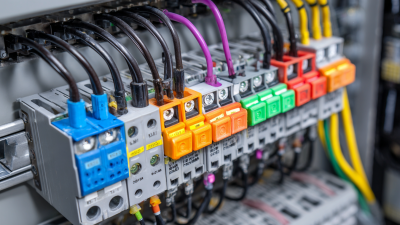

In the realm of modern automation solutions, the significance of PLC connectors cannot be overstated. These critical components play an essential role in ensuring reliable communication between programmable logic controllers and various industrial devices. According to a recent report by MarketsandMarkets, the global industrial automation market size is projected to reach USD 296.70 billion by 2026, growing at a CAGR of 8.5%. This growth is largely driven by the increasing need for operational efficiency and real-time data processing, where PLC connectors serve as the backbone for seamless connectivity. As industries trend towards more integrated and intelligent systems, understanding the vital contribution of PLC connectors to system performance and interoperability becomes imperative. These connectors not only enhance data exchange but also facilitate advanced control functions, positioning them as a key element in the evolution of automation technologies.

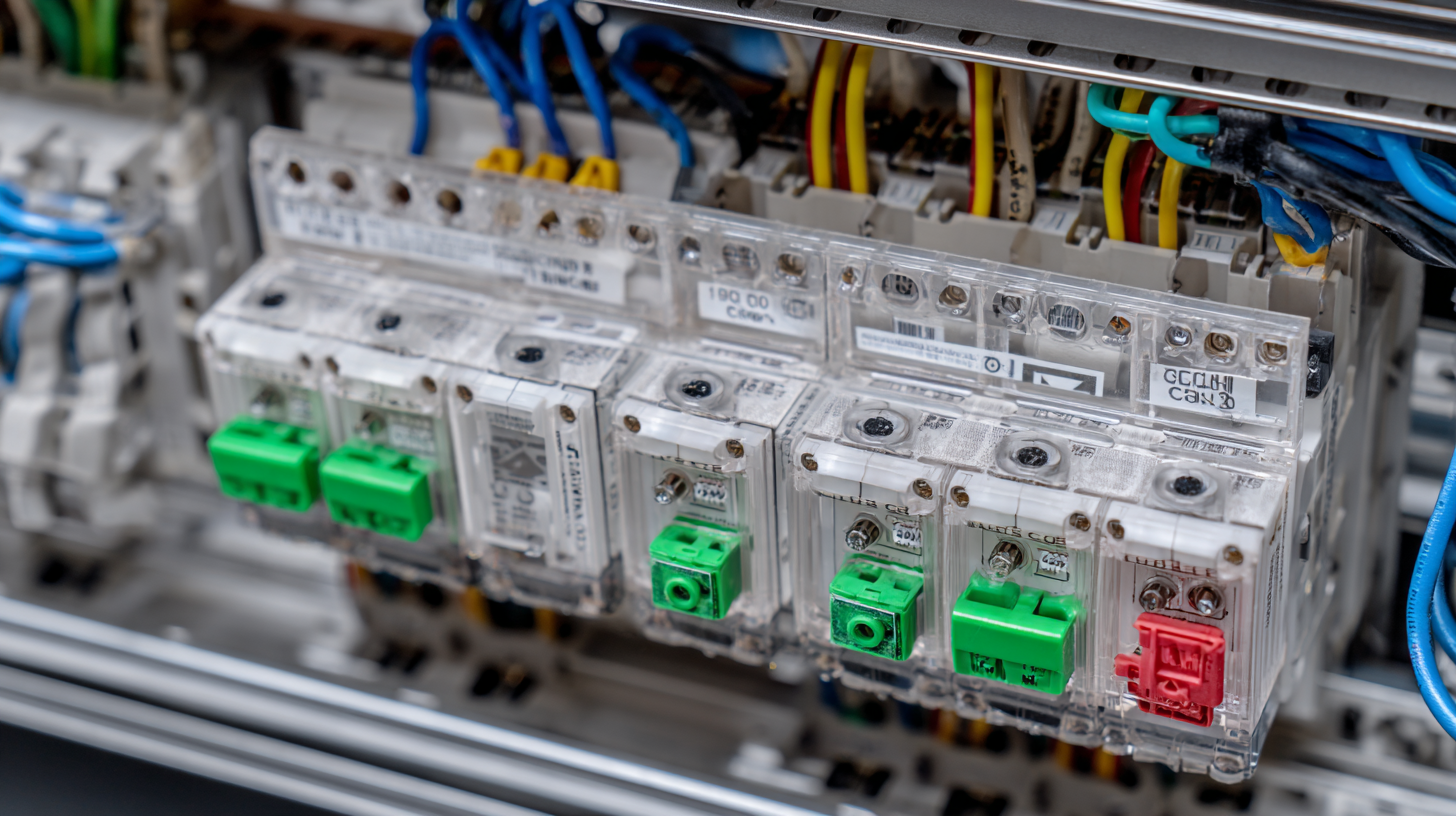

In the realm of modern automation solutions, PLC connectors play a crucial role in enhancing system efficiency and reliability. According to a report by the International Society of Automation, the integration of reliable connectors can improve system uptime by up to 30%. This enhancement is vital as manufacturers strive for continuous operations and minimal downtime, particularly in industries such as automotive and manufacturing where automation is key to productivity.

PLC connectors ensure seamless communication between various components of automation systems. Their design minimizes the risk of connection failures, which can lead to costly delays. As automation systems become more complex, the quality of these connectors directly influences overall system performance. Studies indicate that investing in high-quality PLC connectors can reduce maintenance costs by approximately 20%, making them an indispensable asset in today's automation landscape.

**Tip:** When selecting PLC connectors, prioritize those with high resistance to environmental factors such as moisture, dust, and temperature fluctuations to enhance the longevity and reliability of your automation systems.

**Tip:** Regularly inspect and maintain PLC connectors to ensure optimal performance and prevent unexpected downtime in your operations. Keeping the connections clean and secure can lead to significant long-term operational efficiency.

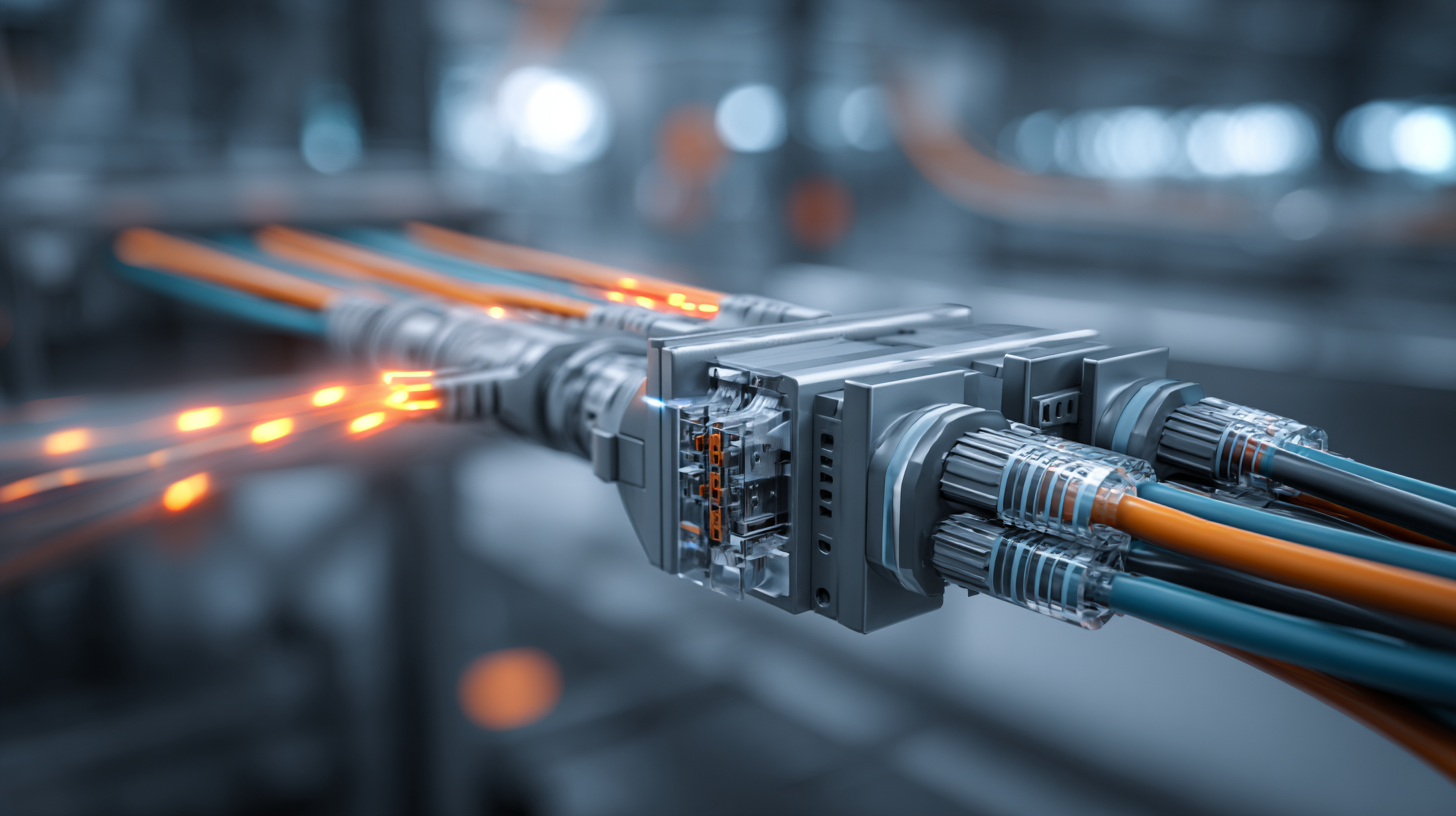

The adoption of PLC connectors in modern automation solutions is witnessing a transformative wave, driven by several key industry trends. According to a recent report by MarketsandMarkets, the global PLC market is expected to reach USD 25 billion by 2026, growing at a CAGR of 5.5%. This growth is largely propelled by the increasing demand for automation in various sectors, including manufacturing, oil and gas, and water treatment. As industries strive for efficiency and cost-effectiveness, the integration of PLC connectors into systems is becoming a critical component of strategic planning.

In this evolving landscape, understanding how to effectively integrate PLC connectors can make a significant difference. Industry experts suggest focusing on modular design and ease of connectivity to enhance system scalability and maintenance. For instance, adopting standardized connectors reduces compatibility issues and streamlines troubleshooting processes.

Tip: When selecting PLC connectors, consider their environmental ratings to ensure resilience in challenging conditions. Investing in high-quality, durable connectors can minimize downtime and enhance operational reliability. By staying abreast of these trends and leveraging the right integration strategies, companies can position themselves at the forefront of automation technology.

In modern automation solutions, PLC (Programmable Logic Controller) connectors play a crucial role in enhancing operational efficiency. One of the significant impacts of PLC connectors is their ability to reduce downtime. By facilitating quick and reliable connections between various automation components, these connectors ensure seamless communication within industrial systems. When issues arise, easy access and replaceability of PLC connectors allow for rapid troubleshooting, minimizing disruptions in production processes.

Moreover, the longevity and durability of high-quality PLC connectors contribute significantly to lowering maintenance costs. With robust designs that can withstand harsh industrial environments, these connectors reduce the frequency of replacements. This not only saves on material costs but also diminishes the labor costs associated with frequent maintenance interventions. As a result, businesses can allocate resources more effectively, focusing on core operations instead of dealing with ongoing connectivity issues. In an era where efficiency is paramount, investing in reliable PLC connectors becomes essential for sustainable automated solutions.

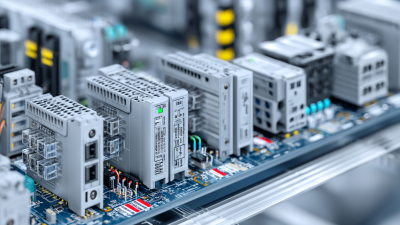

Technological advancements in PLC connectors play a crucial role in shaping modern automation solutions. With the industrial automation market projected to reach $214 billion by 2026, the demand for efficient and reliable connectors is more pronounced than ever. These connectors facilitate seamless communication between programmable logic controllers (PLCs) and various industrial devices, ensuring real-time data transfer and operational efficiency. According to a recent report by MarketsandMarkets, the global PLC market is expected to grow at a CAGR of 5.8% from 2021 to 2026, highlighting the integral role of connectors in this expansion.

Moreover, the evolution of PLC connectors has been driven by the need for enhanced performance and interoperability. Innovations such as the development of smart connectors, which incorporate IoT capabilities, allow for advanced diagnostics and predictive maintenance. A study by Frost & Sullivan indicated that adopting advanced connector technologies could reduce downtime by up to 30%, significantly impacting productivity. As industries gravitate towards smarter solutions, the enhancement of PLC connectors remains a driving force, enabling manufacturers to implement more automated processes and embrace Industry 4.0 principles.

PLC connectors play a crucial role in modern automation solutions, facilitating seamless communication between various devices and systems.

In recent case studies, industries have demonstrated significant improvements in efficiency and reliability due to effective implementations of PLC connectors.

For instance, a manufacturing plant integrated PLC connectors in their assembly line to streamline data transmission between sensors and control systems. This resulted in real-time monitoring of production processes, drastically reducing downtime and enhancing productivity.

Another notable example is in the energy sector, where a utility company adopted PLC connectors to manage its smart grid system. By connecting distributed energy resources with centralized control units, the company enhanced its ability to respond to fluctuations in energy supply and demand.

The implementation not only improved grid stability but also maximized the use of renewable energy sources, showcasing the versatility and impact of PLC connectors in modern automation systems.

These case studies highlight the essential role of PLC connectors in driving innovation and efficiency across various industries.