In the world of industrial automation and machinery, the significance of selecting the right Industrial Connector cannot be overstated. These connectors serve as vital communication links, ensuring seamless data transfer and reliable power management in various applications. With an array of types available, ranging from circular and rectangular connectors to specialized connectors for harsh environments, making the right choice can greatly enhance system performance and longevity. This guide aims to demystify the process of selecting the optimal Industrial Connector by exploring their various types, applications, and critical features. By understanding the nuances of each type, you will be better equipped to improve efficiency, minimize downtime, and ultimately boost the productivity of your operations.

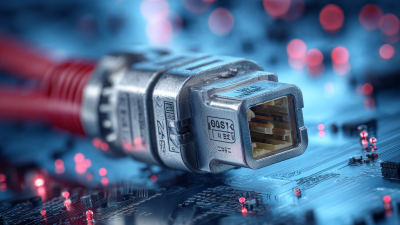

When it comes to industrial applications, understanding the various types of connectors available is crucial for ensuring optimal performance. Industrial connectors come in a multitude of shapes, sizes, and specifications, each designed to meet distinct operational demands. Some of the most common types include circular, rectangular, and modular connectors. Circular connectors, for instance, are renowned for their ruggedness and are often used in applications where vibration and environmental exposure are concerns. On the other hand, rectangular connectors are popular for their space-saving capabilities and ease of assembly, making them ideal for control panels and machinery.

Additionally, the application of these connectors plays a critical role in their selection process. For automated systems, connectors must provide reliable signal transmission, whereas power applications necessitate heavy-duty connectors that can handle high current loads. Understanding the environment in which the connectors will be used—such as temperature fluctuations, moisture levels, and the presence of chemicals—can guide users in selecting the right type. By carefully assessing both the types of connectors available and their specific applications, industrial designers and engineers can ensure efficient operations and extended service life for their systems.

This chart illustrates the data transfer efficiency of various industrial connector types. Circular connectors and USB connectors perform at the highest efficiency, while DIN connectors show the lowest performance among the types evaluated.

When selecting the right industrial connector for optimized performance, several key considerations come into play. Firstly, understanding the specific application environment is critical. For instance, connectors utilized in military or aerospace sectors are meticulously designed to meet stringent requirements concerning size, weight, cost, and throughput. Reports indicate that choosing the appropriate connector can significantly enhance system reliability and efficiency, making it a priority during the design and upgrade phases.

When selecting the right industrial connector for optimized performance, several key considerations come into play. Firstly, understanding the specific application environment is critical. For instance, connectors utilized in military or aerospace sectors are meticulously designed to meet stringent requirements concerning size, weight, cost, and throughput. Reports indicate that choosing the appropriate connector can significantly enhance system reliability and efficiency, making it a priority during the design and upgrade phases.

Additionally, the type of connector should align with the expected data transmission rates and environmental factors. Modern connectors must handle higher bandwidth demands and resiliently withstand various temperatures and physical stresses. Data reveals that companies opting for precision-engineered connectors can reduce failure rates by up to 30%, showcasing the importance of making informed selections. Moreover, installation aspects, such as ease and compatibility, cannot be overlooked, as these can affect both the immediate performance and long-term upkeep of the system. By prioritizing these considerations, businesses can ensure a smooth integration of connectors that supports their operational goals.

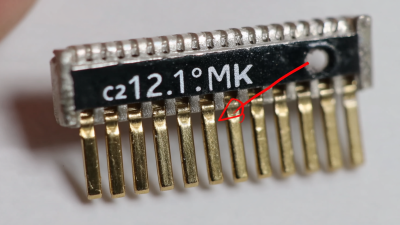

When selecting an industrial connector, evaluating performance factors is crucial for ensuring optimal functionality in demanding environments. One of the primary considerations is the connector's durability. Industrial connectors must withstand harsh conditions, including extreme temperatures, moisture, and vibrations. Materials like stainless steel and high-grade plastics are often preferred for their resilience, providing the necessary resistance to environmental stressors. Additionally, the design of the connector plays a significant role in its overall performance; features such as locking mechanisms and shielding can enhance protection against physical impacts and electromagnetic interference.

Another key performance factor is the electrical characteristics of the connectors. Ensuring that the connector can handle the required current and voltage levels without degrading over time is essential for sustaining performance. Look for connectors with advanced contact designs that minimize resistance and optimize conductivity. Furthermore, consider the ease of installation and maintenance; connectors that are user-friendly can greatly reduce downtime and improve operational efficiency. By carefully evaluating these performance aspects, industries can make informed choices that enhance system reliability and longevity.

When selecting industrial connectors, it's crucial to avoid common pitfalls that can compromise performance. One frequent mistake is underestimating the environmental conditions in which the connectors will be used. For instance, selecting a connector that is not rated for temperature fluctuations or exposure to moisture can lead to early failure. Always consider the specific environmental factors, such as humidity, dust, and temperature, to ensure longevity and reliability.

Another common error is neglecting to assess the electrical requirements of the application. Choosing a connector without verifying the voltage and current specifications may result in insufficient power delivery or even damage to the equipment. Ensure that the selected connector matches the necessary power requirements and has appropriate impedance to maintain optimal performance.

Lastly, don’t overlook the importance of mechanical durability. Many connectors are subjected to physical stress in industrial environments, and selecting a poorly built option can lead to frequent replacements. Opt for connectors designed for industrial use, featuring rugged housings and secure locking mechanisms to withstand vibration and harsh handling. By being mindful of these factors, you can make informed decisions that enhance the performance and lifespan of your industrial electrical systems.

| Connector Type | Common Applications | Key Features | Potential Mistakes | Optimal Choices |

|---|---|---|---|---|

| Circular Connectors | Robotics, Heavy Machinery | Durable, Easy to Connect | Ignoring environment ratings | Choose weatherproof options |

| Rectangular Connectors | Telecommunications, Industrial Automation | High Density, Modular | Not considering space constraints | Evaluate layout requirements |

| USB Connectors | Consumer Electronics, Data Transfer | Universal Compatibility, Easy Use | Overlooking power requirements | Check voltage and current ratings |

| Fiber Optic Connectors | Telecommunications, Networking | High-Speed Data Transfer, Low Signal Loss | Neglecting cleanliness during installation | Use dust caps and clean with appropriate tools |

| Power Connectors | Industrial Equipment, Power Tools | High Current Rating, Robust Design | Choosing connectors with inadequate ratings | Match connector with application needs |

As industries evolve, the importance of selecting the right connectors becomes paramount, especially with the advent of emerging technologies. Recent studies indicate that the industrial connector market is expected to grow at a CAGR of 5.6% from 2023 to 2028. This growth is driven by advancements in automation and the increasing implementation of IoT devices across manufacturing processes. The latest connector designs incorporate features such as higher data rates and improved ruggedness, responding to the demands of modern industrial environments.

One key trend is the development of connectors that support advanced data transmission standards, such as Ethernet and USB 3.0. Reports show that connectors enabling data transfer rates of up to 10 Gbps are becoming increasingly popular, reflecting a shift towards faster and more efficient communication systems in industrial settings.

Furthermore, the integration of smart technology within connectors, including condition monitoring and predictive maintenance capabilities, is anticipated to enhance operational efficiency, reducing downtime and maintenance costs. As industries embrace these innovations, the focus will undoubtedly remain on connectors that can sustain the rigors of the future while providing optimized performance for an increasingly digital landscape.