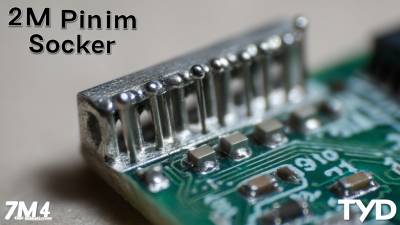

In the ever-evolving landscape of connectivity solutions, the 2mm Pin Header Socket stands out as a pivotal component driving innovation and enhancing electronic design flexibility. As industries continue to demand higher efficiency, miniaturization, and reliable connectivity, advancements in the design and functionality of 2mm Pin Header Sockets are at the forefront of addressing these challenges. This blog will delve into the future of these sockets, exploring their emerging trends, technological advancements, and the underlying reasons why they are becoming increasingly essential in modern electronics.

From automotive applications to consumer electronics, we will uncover how these seemingly simple connectors are revolutionizing the way devices communicate and operate, paving the way for a smarter, more connected world. Join us as we explore the multifaceted benefits and transformative potential of the 2mm Pin Header Socket in shaping the future of connectivity solutions.

The advancements in 2mm pin header socket designs are pivotal for enhancing performance across multiple sectors. As industries lean towards compact solutions without compromising on efficiency, the demand for high-density connectors is growing. Recent industry reports indicate that the PCB connector market is projected to reach USD 46.31 billion by 2034, driven by innovations that cater specifically to high-performance applications. These advancements not only ensure better power delivery but also accommodate evolving technologies in electric vehicles and high-speed data transfer.

Innovative designs, such as modular connectors, are creating boundless possibilities for customization, enabling engineers to configure their connectivity solutions to specific operational needs. Similarly, recent developments in rugged connectivity are addressing the rigorous demands of aerospace and defense applications, where lightweight and robust solutions are crucial.

The trend of incorporating advanced safety features into power connectors, as seen in new designs being tested, further highlights the industry's commitment to improving overall performance and reliability in connectivity solutions, setting the stage for the next generation of electronic integration.

The 2mm pin header socket has become an integral component in the realm of modern electronics, playing a pivotal role in enhancing connectivity solutions across a multitude of applications. As devices continue to shrink in size while increasing in functionality, the demand for compact and reliable connectors has surged. The 2mm pin header socket, with its minimal footprint and robust design, addresses this need effectively, allowing for seamless connections in everything from consumer electronics to industrial automation.

One of the key advancements in 2mm pin header socket technology is their improved durability and performance in challenging environments. Manufacturers are now utilizing high-quality materials and innovative designs to ensure that these sockets can withstand vibrations, temperature fluctuations, and other external stressors common in various applications. Moreover, with the rise of modular systems and the Internet of Things (IoT), the adaptability of 2mm pin header sockets aligns perfectly with the trend towards customization and easy reconfiguration, enabling designers to create flexible and scalable solutions that meet evolving technological demands.

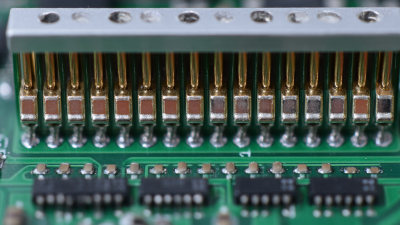

As the demand for compact and efficient connectivity solutions continues to rise, miniaturization in pin header technology has become a key focus for manufacturers. According to a recent report by Technavio, the global market for pin header sockets is expected to grow by 8.5% annually through 2025, fueled by advancements in electronics and the proliferation of smaller devices. This trend points toward a need for connectors that not only save space but also maintain high performance levels in increasingly complex applications.

In this pursuit of efficiency, manufacturers are exploring innovative materials and design methodologies. For instance, using advanced materials like LCP (Liquid Crystal Polymer) can enhance thermal stability while allowing for thinner profiles, thus meeting the needs of high-density circuit designs. Furthermore, the integration of automated assembly processes is not only streamlining production but also improving the accuracy and reliability of connections.

As we look forward, the combination of miniaturization and efficiency in pin header technology is setting the stage for a new era of connectivity solutions that cater to the evolving landscape of wearable technology, IoT devices, and smart electronics.

As the demand for compact and efficient connectivity solutions continues to grow, 2mm pin headers are stepping into the spotlight as a pivotal component in modern electronics. These pin headers offer a reliable way to address connectivity challenges, particularly in devices where space is a premium. With advancements in design and functionality, the integration of 2mm pin header sockets into printed circuit boards (PCBs) presents engineers with a reliable alternative for ensuring optimal connections without the bulk of traditional connectors.

Recent innovations reflect a trend toward miniaturization and enhanced connectivity, exemplified by replacements for larger programming headers. Utilizing a connector based on pogo-style pins allows for direct PCB connections without the need for onboard mating connectors. This method not only simplifies the design process but also enhances the overall reliability of the device, reducing potential failure points. Such developments in 2mm pin header technology show promise in overcoming connectivity challenges, setting the stage for more streamlined and efficient electronic designs.

The adoption of 2mm pin header sockets has been rapidly increasing across various industries, thanks to their compact design and reliability. In the telecommunications sector, companies have successfully integrated these sockets into their devices to enhance connectivity and streamline manufacturing processes. One notable case study involved a telecommunications firm that reduced assembly time by 20% by switching to 2mm pin headers, significantly improving their overall efficiency. This move not only minimized production costs but also ensured robust connections, essential for high-performance equipment.

In the automotive industry, 2mm pin header sockets have revolutionized electronic component integration. A leading automotive manufacturer implemented these sockets in their control units, resulting in a more modular design. This modularity allows for easier updates and repairs without needing to overhaul entire systems. The result has been a more agile production line and a reduction in vehicle downtime, showcasing the flexibility that these connectors provide.

**Tips:** When selecting 2mm pin header sockets for your projects, consider factors like the pin count and orientation to ensure compatibility with your components. Additionally, for better durability, opt for sockets with anti-microbial coatings, especially for devices used in critical healthcare applications. Finally, always assess the environmental impact of your chosen connectors to align with sustainable practices.