In today's fast-paced and technology-driven manufacturing landscape, effective connectivity is paramount for operational efficiency and productivity. According to a report by MarketsandMarkets, the industrial connectors market is projected to reach USD 10.83 billion by 2025, growing at a CAGR of 5.2%. This highlights the increasing reliance on robust Industrial Connectors to ensure seamless communication and data transfer between machinery and infrastructure.

As industries strive for digital transformation and IoT integration, selecting the right connectors becomes critical to overcoming challenges such as interoperability, reliability, and high-speed data transmission. This ultimate guide aims to explore innovative solutions for enhancing connectivity through Industrial Connectors, equipping manufacturers with insights necessary for optimizing their systems and paving the way for a more connected and efficient future.

As industries strive for digital transformation and IoT integration, selecting the right connectors becomes critical to overcoming challenges such as interoperability, reliability, and high-speed data transmission. This ultimate guide aims to explore innovative solutions for enhancing connectivity through Industrial Connectors, equipping manufacturers with insights necessary for optimizing their systems and paving the way for a more connected and efficient future.

In the landscape of modern manufacturing, industrial connectors play a pivotal role in enhancing connectivity and streamlining operations. As machinery becomes increasingly sophisticated, the demand for reliable and efficient connections among various components grows. Industrial connectors serve as the backbone of these systems, ensuring seamless communication between machines, sensors, and control units. Their robust design and ability to withstand harsh environments make them ideal for a wide range of applications, from assembly lines to automated production systems.

Understanding the role of industrial connectors goes beyond just their basic function; it involves recognizing how they contribute to overall system efficiency. These connectors are engineered to support high data transfer rates and durability, which is essential for real-time monitoring and control in manufacturing processes. Furthermore, they facilitate the integration of advanced technologies like IoT and Industry 4.0, creating a more interconnected and responsive manufacturing ecosystem. As manufacturers aim to optimize productivity and reduce downtime, the strategic implementation of industrial connectors becomes crucial in driving operational excellence.

| Connector Type | Application Area | Data Transmission Speed | Environmental Rating | Key Features |

|---|---|---|---|---|

| M12 Connectors | Factory Automation | 100 Mbps | IP67 | Compact, Rugged |

| RJ45 Connectors | Networking | 1 Gbps | Standard | Versatile, Cost-effective |

| USB Industrial Connectors | Data Collection | 480 Mbps | IP65 | High-speed, User-friendly |

| Circular Connectors | Robotic Systems | Up to 10 Gbps | IP68 | Durable, Reliable |

| DIN Connectors | Process Control | Up to 1 Gbps | IP54 | Versatile, Easy to Install |

In today's rapidly evolving manufacturing landscape, the choice of industrial connectors plays a crucial role in maintaining robust connectivity and ensuring seamless communication between systems. Industrial connectors come in various types, including circular connectors, rectangular connectors, and cable assemblies, each tailored for specific applications. According to a report by Research and Markets, the global industrial connectors market is expected to reach USD 7.8 billion by 2026, driven by the increasing automation and the demand for reliable communication networks in factories.

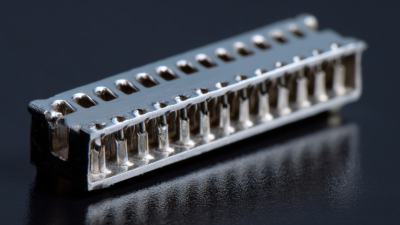

Circular connectors, for instance, are commonly used in machinery and automation processes due to their excellent sealing properties and ability to withstand harsh environments. Meanwhile, rectangular connectors are often employed in control systems and power distribution, where higher pin density is required. Additionally, industry reports indicate that the adoption of connectors with advanced features, such as tooling and IP68 ratings, is surging, as manufacturers seek enhanced durability and ease of maintenance. This growing trend underscores the importance of selecting the right type of industrial connector to achieve optimal performance and reliability across all facets of modern manufacturing.

In modern manufacturing, the selection of the right industrial connectors plays a critical role in ensuring seamless connectivity and efficient operations. One of the best practices for choosing suitable connectors is understanding the specific requirements of your application. Consider factors such as environmental conditions, expected data transmission speeds, and the types of devices being interconnected. For instance, connectors used in harsh environments should have rugged designs that can withstand extreme temperatures, moisture, and mechanical stress, ensuring longevity and reliability.

Another essential aspect is compatibility. When selecting connectors, it’s important to ensure they are compatible with the existing infrastructure and equipment. This includes considering the type of signals being transmitted—whether power, data, or both—and ensuring that the connector can handle the necessary load without risk of failure.

Furthermore, engaging with manufacturers to understand their offerings and seeking recommendations based on your operational needs can lead to better-informed decisions that enhance overall connectivity in your manufacturing processes. By prioritizing these practices, manufacturers can improve efficiency and reduce downtime, ultimately leading to greater productivity.

In modern manufacturing, the integration of advanced industrial connectors has become crucial for improving machine connectivity and operational efficiency. According to a recent report by MarketsandMarkets, the global industrial connectors market is projected to grow from $3.68 billion in 2021 to $5.48 billion by 2026, at a compound annual growth rate (CAGR) of 8.2%. This growth is driven by increasing automation and the adoption of Industry 4.0 practices, emphasizing the need for reliable and high-performance connectors that can handle diverse applications in harsh industrial environments.

To successfully integrate advanced connectors, manufacturers should begin by assessing their existing connectivity infrastructure. This includes evaluating the types of connectors currently in use and identifying any limitations that may hinder performance or scalability. Implementing connectors with enhanced features—such as higher pin density, ruggedized designs, and modular configurations—can facilitate better signal integrity and reduce downtime.

Data from IDC indicates that companies enhancing their connectivity solutions can achieve up to a 25% increase in machine productivity, underscoring the tangible benefits of investing in advanced connector technologies. Establishing partnerships with specialized connector manufacturers can also provide access to customized solutions that meet specific operational needs, ultimately driving greater innovation and efficiency in the production process.

In the rapidly evolving landscape of modern manufacturing, maintaining industrial connectors is paramount for long-term performance and reliability. As manufacturers increasingly rely on the Internet of Things (IoT) and edge computing technologies to streamline operations, the integrity of their connectivity solutions becomes critical. Industrial connectors must withstand not only the rigors of daily use but also the environmental challenges commonly found in manufacturing setups. Regular maintenance practices, including cleaning, visual inspections, and timely replacements, are essential to ensure that these connectors continue to perform optimally and minimize downtime.

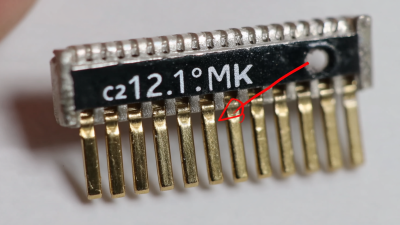

Recent advancements in technology, such as the introduction of new embedded processors designed for low-latency applications, highlight the growing demands on industrial connectivity. These processors cater to the need for real-time computational performance while maintaining cost efficiency, paving the way for robust edge computing solutions in manufacturing environments. The seamless integration of these technologies with well-maintained industrial connectors strengthens the overall system reliability and enhances operational efficiency, ultimately driving innovation and growth in the industry. By prioritizing maintenance and adopting cutting-edge technologies, manufacturers can ensure that their connectivity remains resilient and reliable amid the challenges of modern production demands.