In today's rapidly evolving global marketplace, businesses are increasingly seeking efficient and reliable solutions to enhance their sourcing strategies. One such innovation that has gained significant traction is the In Out Connector, a technology that not only streamlines operations but also bridges geographical gaps. According to a recent industry report by MarketsandMarkets, the global connectors market is projected to reach $113.2 billion by 2026, driven by the demand for advanced interconnect solutions. The rise of e-commerce and the push for automation in supply chains further underscore the importance of adopting cutting-edge technologies like In Out Connectors. These connectors facilitate seamless integration and communication across diverse platforms, enabling companies to optimize their sourcing processes and respond swiftly to market dynamics. As businesses strive to enhance efficiency and reduce costs, understanding the compelling reasons to choose In Out Connectors has never been more crucial.

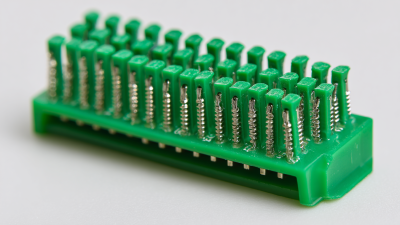

In today's global supply chains, choosing the right connectors is crucial for ensuring seamless operations. In Out Connectors stand out due to their innovative design and functional benefits. According to a report by Supply Chain Dive, integrating effective connectors can improve operational efficiency by up to 30%, significantly reducing lead times and enhancing collaboration between various stakeholders in the supply chain.

One of the primary advantages of In Out Connectors is their ability to facilitate real-time data exchange. The World Economic Forum estimates that leveraging advanced data connectivity in supply chains could unlock $5 trillion in value by 2025. This capability not only fosters transparency but also aids in timely decision-making, which is critical in today’s fast-paced market environment. Furthermore, these connectors are designed to adapt to various systems and frameworks, providing the flexibility that global sourcing operations demand, ensuring organizations can pivot quickly in response to market changes.

Moreover, the durability and low maintenance requirements of In Out Connectors significantly lower the total cost of ownership. A study published by Gartner reveals that companies can save up to 20% on maintenance costs when using reliable connector solutions, making these connectors a smart investment for businesses aiming to streamline their supply chain processes while optimizing their budget. This combination of efficiency, adaptability, and cost-effectiveness positions In Out Connectors as a top choice for organizations navigating the complexities of global sourcing.

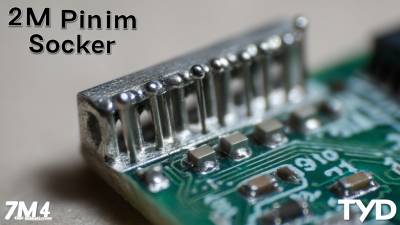

In today’s competitive global market, selecting the right components can significantly impact product quality and reliability. In Out Connectors stand out due to their robust design and superior performance, ensuring that they maintain consistent electrical connections even under challenging conditions. This reliability reduces the risk of failures that could lead to costly downtime and repairs, making them an ideal choice for manufacturers prioritizing quality in their sourcing strategies.

Moreover, the innovative design of In Out Connectors facilitates easier integration with various systems, enhancing the overall efficiency of the final product. Their versatility allows for seamless adjustments during the assembly process, which is crucial for meeting diverse market demands. By choosing In Out Connectors, businesses not only enhance the performance of their products but also align with stringent regulations and quality standards, ultimately leading to greater customer satisfaction and trust in their brand.

In today’s competitive landscape, cost-effectiveness is crucial for companies looking to streamline their global sourcing processes. In Out Connectors offer a compelling solution that enables businesses to optimize their purchasing decisions efficiently. By integrating these connectors, procurement teams can achieve significant cost savings while ensuring that their sourcing strategies are aligned with the latest sustainability initiatives. With the growing emphasis on sustainable purchasing, the ability to make informed decisions that balance cost and environmental responsibility is a game-changer.

Furthermore, the adaptability of In Out Connectors can enhance supplier relationship management. By facilitating clear communication and collaboration across international borders, companies can maintain strong partnerships while also leveraging the latest innovations in quality control. Cases of successful implementation in various industries demonstrate that organizations can not only reduce costs but also improve overall efficiency and product quality. Investing in In Out Connectors allows businesses to stay ahead in the global market by embracing cost-effective and sustainable sourcing practices.

In the dynamic landscape of global sourcing, the efficiency of logistics processes is paramount. In Out Connectors serve as pivotal tools that streamline these operations, enabling businesses to navigate complex supply chains with ease. By facilitating quick and reliable connections between suppliers and distribution networks, these connectors minimize delays and reduce costs. Their design inherently supports flexibility, allowing for seamless integration into various logistical frameworks, adapting to the unique demands of diverse industries.

Moreover, In Out Connectors enhance communication and visibility across the supply chain. With real-time data exchange capabilities, they empower stakeholders to make informed decisions swiftly, improving responsiveness to market fluctuations. This not only boosts operational efficiency but also fosters stronger partnerships among suppliers, manufacturers, and retailers. The use of In Out Connectors ultimately creates a more agile logistical environment, helping businesses stay competitive in an ever-evolving global marketplace.

| Reason | Description | Impact on Logistics |

|---|---|---|

| Cost Efficiency | In Out Connectors help reduce shipping and handling costs. | Lower logistics costs improve overall profit margins. |

| Streamlined Processes | Facilitates better coordination between suppliers and logistics partners. | Enhances efficiency and reduces delays. |

| Improved Tracking | Allows real-time tracking of goods in transit. | Increases transparency and accountability in logistics operations. |

| Flexibility | Easily adapts to various supply chain models. | Supports diverse logistics strategies and partnerships. |

| Scalability | Can handle increasing volume and complexity of logistics operations. | Facilitates growth without compromising service levels. |

| Enhanced Collaboration | Promotes better communication among stakeholders. | Leads to improved problem-solving and innovation. |

| Risk Mitigation | Reduces risks associated with logistical disruptions. | Enhances reliability and customer satisfaction. |

In the dynamic landscape of global sourcing, adapting In Out connectors to meet diverse market needs has become pivotal. The PCB connector market, estimated to elevate from USD 33.82 billion in 2025 to USD 46.31 billion by 2034, underscores the accelerating demand for versatile connectivity solutions. As industries strive for efficiency and customization, In Out connectors are designed to meet these evolving requirements, particularly across different applications and demographics.

Moreover, the growth in the electric plugs and sockets market, projected to reach USD 38.48 billion at a 3.41% CAGR by 2034, highlights the necessity for adaptable connection systems that can seamlessly interface with a variety of electrical environments. This trend of modularity extends to industries like construction machinery, where wiring harnesses are projected to grow at a 4.24% CAGR until 2032, further emphasizing the crucial role of connectors in maintaining operational flexibility and innovation. By leveraging the capabilities of In Out connectors, businesses can ensure they stay ahead in a rapidly evolving global market.